PCB Design Software and Electronics Design News

#PCBdesign #PrintedCircuitBoards #ElectronicsDesign

Jan 12

The Pros and Cons of Having Your Manufacturer Source the Components in Your PCB Design

While having your manufacturer source components for you might seem like the fastest and cheapest option, some difficulties can arise. After a bad experience with counterfeit components, we began sourcing our own components and never looked back. Counterfeit parts are common and incredibly difficult to detect. Having good control over your sources is absolutely essential if you have tight performance or security specifications. Read on to find out more!

Once you’ve finally gotten the green check mark showing that all the rule checks have been passed, it feels like the hard part is over. Now you just have to send the design out and get your final boards back. One small decision here can have a big impact on that process, though. Will the board manufacturer source the components themselves, or will you supply them?

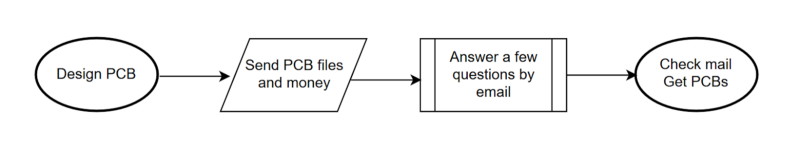

There are advantages to both and I learned this the hard way. When I was fresh out of school and working at a small startup, we needed a rapid turnaround on prototypes. This was when I discovered the time-saving benefits of manufacturer sourcing. It was a fabulous arrangement for our early boards, and it meant that my work process looked like this:

Gosh, I thought, Manufacturer sourcing is great!

· It’s easier: It saves you a lot of effort up front. When you are in the startup crunch or doing beta designs, obvious ways to speed up the process are gold.

· Less paperwork: You don’t have extra purchase orders, custom forms, and internal approvals. It all gets done with the PCB order.

· You don’t re-ship parts: If you’re not receiving parts yourself, you don’t have to consolidate orders and sort parts for the right projects. This is, however, a really good job for interns to do a couple times because they will take a bill of materials (BOM) really seriously afterward.

· Price: It’s usually cheaper. Manufacturers can bulk order their parts and will often share some of the savings with you. You also don’t have to pay for shipping parts to and from your office, only for the final board.

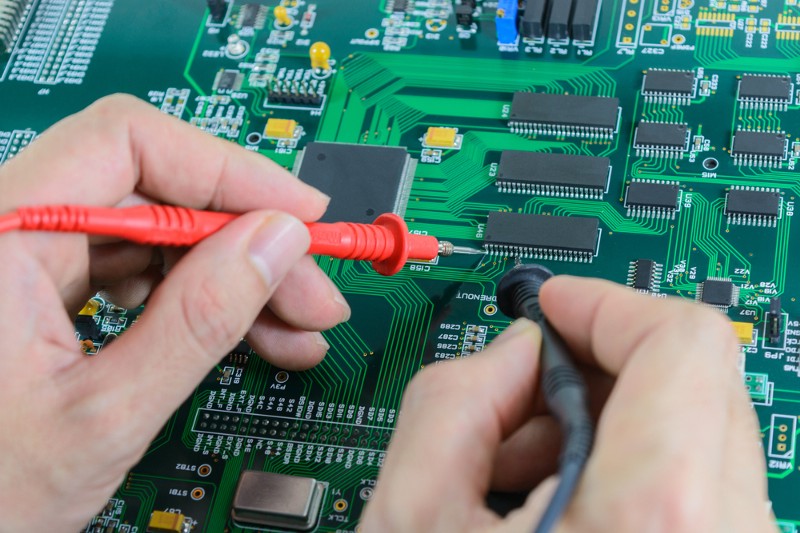

No one wants to spend their nights “cuddled up with a multimeter” troubleshooting their PCBs

Scaling up Production Means Scaling Down on Manufacturer Sourcing

As our product became more successful, we started scaling up production. Just as we thought we were living the “American Dream” our sensor systems started going down and chaos ensued. We spent thousands of dollars replacing the PCBs in those systems, only to find out that most had failed from dead batteries. This led to us questioning whether something on the board was draining the batteries. After spending many late nights cuddled up with our multimeters, we discovered that an integrated circuit (IC) on one batch of boards was drawing a quiescent current almost 100 times higher than specified. The batteries were dropping like flies. As it turns out, the IC was a counterfeit piece, and we spent weeks reworking the boards in-house to replace the bad component.

As a result of this experience, we moved over to sourcing our own components and never looked back. Counterfeit parts are common and incredibly difficult to detect. Having good control over your sources is absolutely essential if you have tight performance or security specifications. Particularly when there’s no efficient or reliable way to verify every component in your final product.

Sourcing your own components is some extra work, but nothing compared to the agony of a bad batch of boards. That being said, my workflow now includes ordering parts, verifying the components, repacking, and shipping them to our manufacturer. That’s two more boxes on my flowchart!

You can make it easier on yourself, though:

· Order parts early: If the schematic and BOM are done, so you’re “only” working on the board layout, you can order your parts now and save some time once you’re ready to build.

· Minimize vendors: One vendor is ideal, but that can be hard to do if you use specialized connectors or RF components.

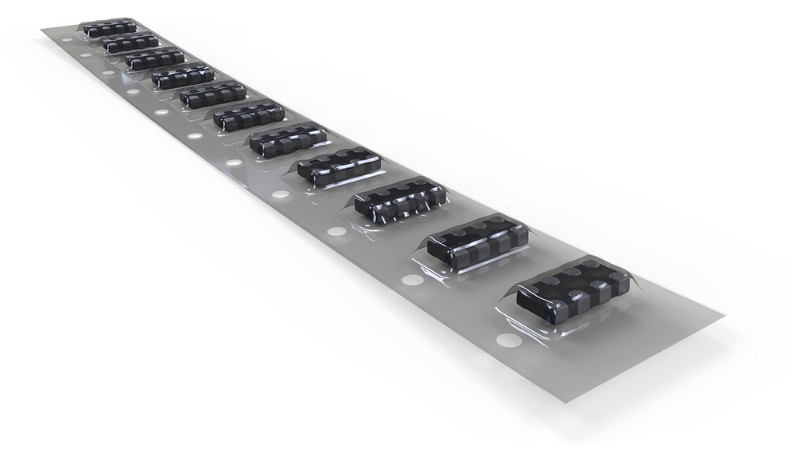

· Check and repack: Use the BOM and invoice together to double check all the components. Then you can repack everything into the box it came in, and re-ship it to the manufacturer.

·Ship directly: Some vendors will ship directly to your board manufacturer, although I recommend doing at least one successful production run first.

Sourcing your own components removes the risk of something going wrong.

What’s best for you depends on your scale and risk tolerance. Shipping a reel of 1,000 pieces obviously makes no sense for a prototype run of ten boards. Once you start to level up in board complexity, the security and performance concerns alone will probably make it worth sourcing components yourself. The headaches you will avoid include:

· Supply chain integrity: The direct translation from MBA-speak is “you know where everything came from.” If you or your customers have concerns about counterfeit parts, this may make the decision for you.

· Performance: Reliable and repeatable sourcing translate directly to performance. If you’re doing multiple manufacturing runs, consistency in your parts is crucial.

· Troubleshooting and deployment speed: In terms of project delays, it will often be faster and cheaper overall to source your own parts, and reduce the risk of future component issues.

A good PCB manufacture can let you make your design dreams a reality. Whether you’re a first-time designer with big ideas for the next great gadget, or an experienced engineer looking to refine your workflow, Juvtmall is better choice for you.

#Juvtmall #PCB #PCBA #hardware

USD

USD EUR

EUR GBP

GBP CAD

CAD AUD

AUD JPY

JPY